Services

PLC-based Control Systems

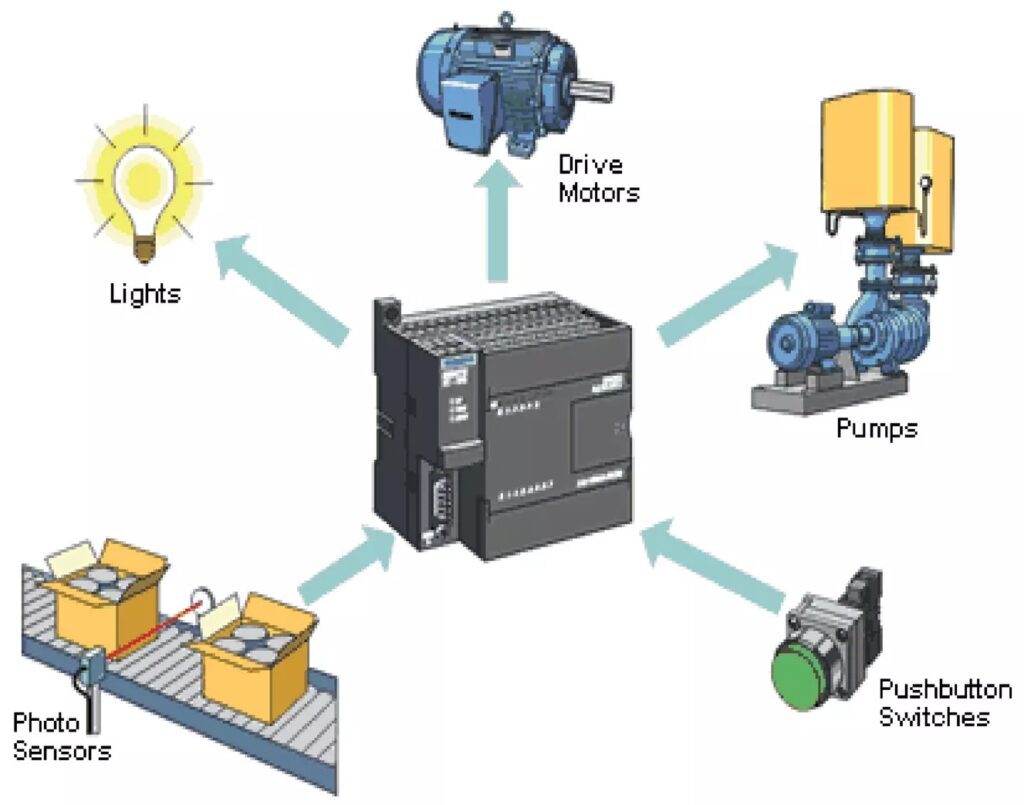

The term PLC stands for Programmable Logic Controller. PLC is a specialized digital controller used in industrial automation to control machinery and processes. PLCs are programmable and the programs can be easily modified to accommodate changes in the process. They have inputs and outputs to interface with sensors, actuators, and other devices. They execute control programs to monitor inputs, make decisions based on logic, and control outputs accordingly.

PLC-based control systems offer enhanced flexibility and reliability in industrial automation. PLCs are designed for harsh industrial environments and have robust hardware. PLCs can communicate with other systems and devices, facilitating integration into larger control systems.

DCS (Distributed Control System)

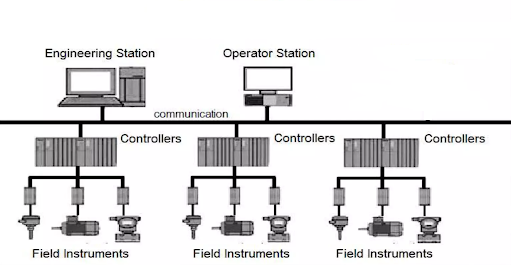

The term DCS stands for Distributed Control System. DCS can automate large and complex processes and provides the ability to monitor the processes and control them. DCS consists of multiple control units distributed in the plant. These units can communicate with each other to coordinate process control and these units also communicate with a centralized human machine interface (HMI) which provides operators with a comprehensive view of the entire process. DCS systems typically include advanced control algorithms and strategies to optimize process performance and improve efficiency.

SIS (Safety Instrumented System)

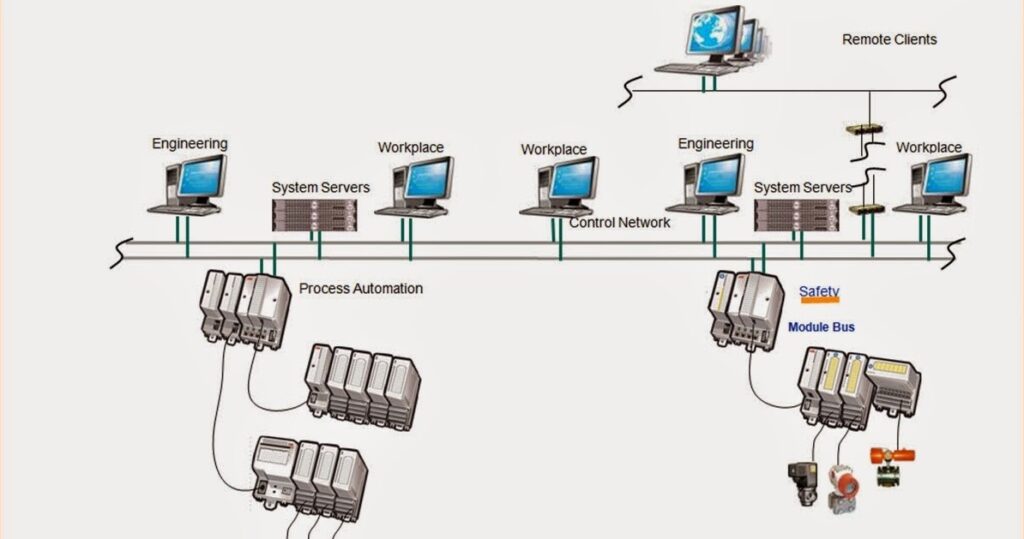

The term SIS stands for Safety Instrumented System. SIS provides protection against various process hazards in a plant and its goal is to reduce the risk of accident or injury. SIS takes automated safety action to keep a plant safe by putting it into a safe state when abnormal conditions are detected, initiating actions such as emergency shutdowns or activation of safety devices to prevent accidents, protect personnel, and safeguard the environment. Because of its criticality, SIS must be independent from all other control systems that control the same equipment, in order to ensure SIS functionality is not compromised.

ICSS (Integrated Control and Safety System)

The term ICSS stands for Integrated Control and Safety System. When Process Control System (PCS) and Safety System (SIS) are integrated as a single system then it is called ICSS. The term ICSS does not imply common system for PCS and SIS. Here, integration stands in ‘operational sense’ and not the design of the system. The safety function will be implemented in SIS but it is integrated with PCS to gain maximum support for plant life-cycle management e.g. common HMI for both control and safety applications. Principles of segregation will be maintained between control and safety strategies.

SCADA Systems

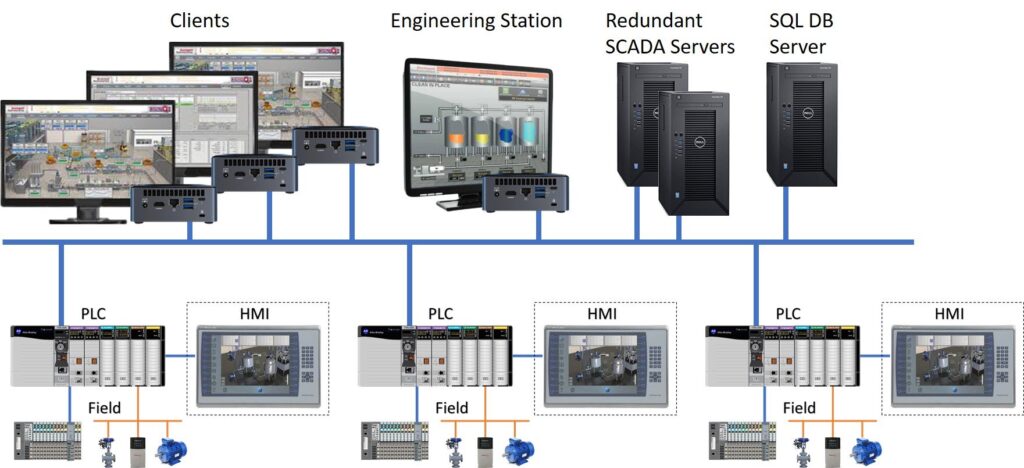

The term SCADA stands for Supervisory Control and Data Acquisition. SCADA systems are used for controlling, monitoring, and analyzing industrial devices and processes. It allows companies to remotely manage industrial sites because the company can access the data and control them without being on site. The site can be spread across different locations, sometimes over a wide geographical area, or contained within a single facility. SCADA systems help optimize the process, control the process, and also help in troubleshooting the issues.

SCADA system consists of a Human Machine Interface (HMI) software installed on a central computer. The HMI provides a graphical representation of the processes and displays data coming from different instruments and devices and it can also provide the functionality to control the devices. SCADA system can also provide the functionality of recording data and events.

The connecting link of SCADA with field instruments and devices are the Programable Logic Controllers (PLCs) or Remote Terminal Units (RTUs). Field instruments and devices are connected to PLCs or RTUs and the SCADA communicates with those PLCs or RTUs.

Complete Automation Project Lifecycle

– Design and Engineering

– Drawings and Documentation

– Procurement

– PLC and HMI Application Development

– Factory Acceptance Testing

– Commissioning

– Site Acceptance Testing

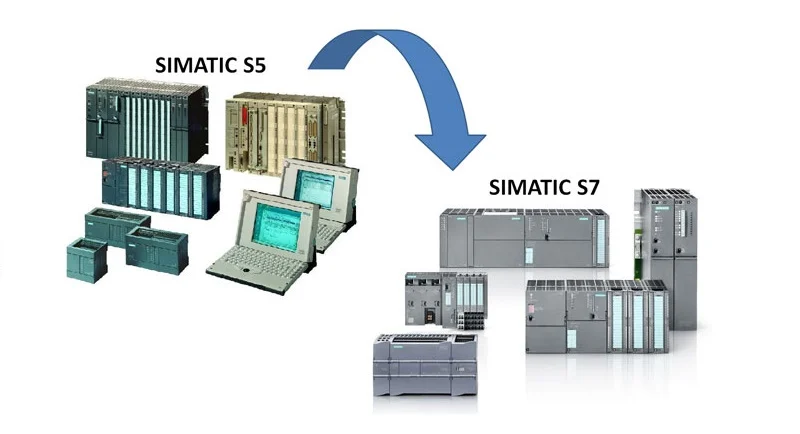

Upgradation/Migration of Systems

The upgradation or migration of control systems, safety systems, and SCADA systems is crucial for enhancing efficiency, improving safety, ensuring reliability, complying with regulations, and future-proofing operations. It is an investment in the long-term success, sustainability, and resilience of industrial organizations.

Utilize our expertise to seamlessly upgrade or migrate your control systems, safety systems, and SCADA systems.

Site Services

– Commissioning Services

– On-Site Troubleshooting/Modifications

– Remote Support

– Operation and Maintenance Services

Other Services

– Cyber Security Implementation

– IIOT Implementation

– Field Instrumentation